Introduction:

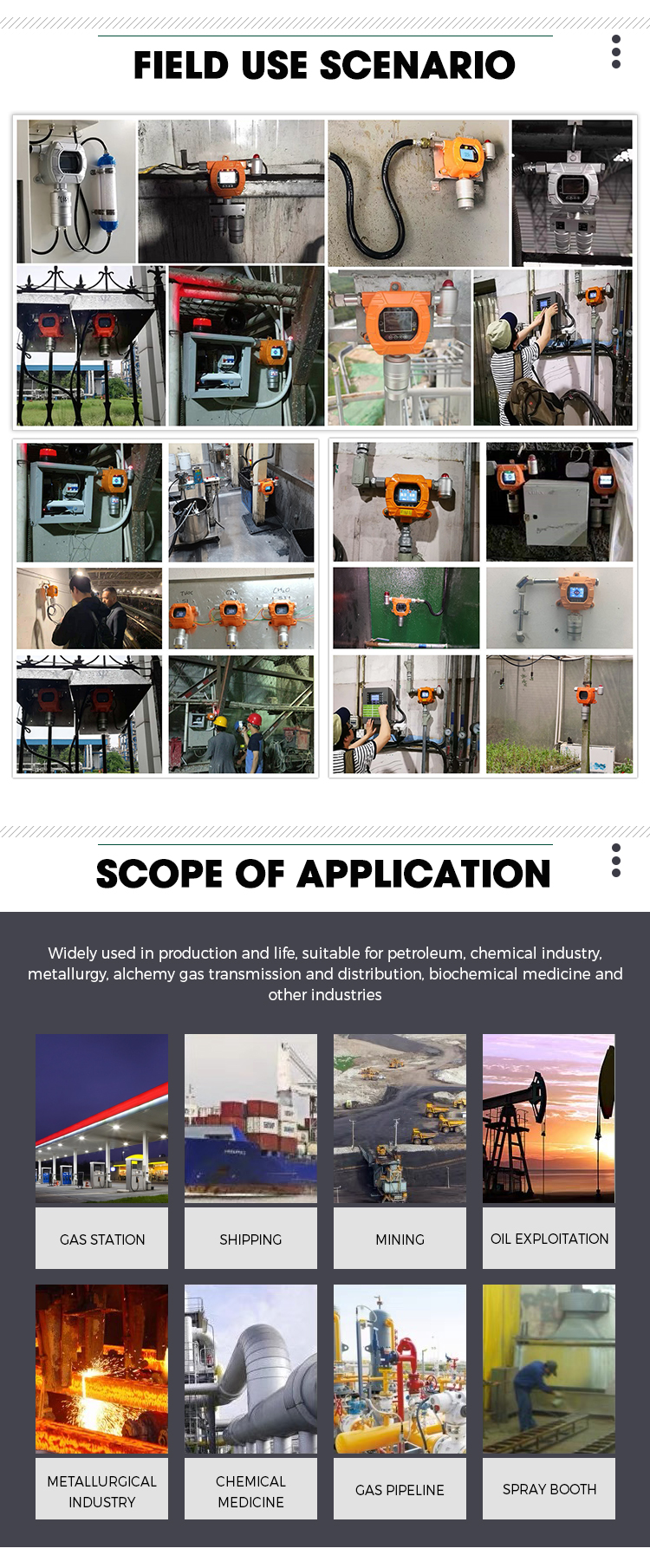

It is used for on-site gas concentration detection and alarm for excessive gas concentration. It can detect the concentration of various toxic and harmful flammable gases, and display the real-time concentration value and standard signal output on the spot.

Use imported brand gas sensors (Honeywell, Japan Nemoto, British CITY, British Alpha, British Dynament, Swiss Membrapor, etc.) gas sensors,

The main detection principles are: electrochemistry, infrared, catalytic combustion, thermal conductivity, PID photoion. It has the advantages of stable signal, high sensitivity and precision, and the flameproof wiring method is suitable for various dangerous places.

Features:

●Intrinsically safe circuit design, explosion-proof certification, secondary lightning protection, anti-static, lightning protection and anti-static capabilities exceed national standards, and resist the impact of high-intensity pulse surge current. High reliability and stability. Anti-reverse connection design, any form of reverse connection will not damage the instrument

●It complies with EMI and EMC standards, and has passed national standard testing and CPA measurement instrument permit type certification.

●Standard bus RS485 (RTU) and 4-20mA standard signal are output at the same time, 3 groups of relay switch output, on-site sound and light alarm (optional). Optional frequency output 200-1000Hz, Hart protocol signal, 1~5V output, wireless transmission (2~5km or unlimited distance). Wired or wireless remote real-time monitoring can be performed. Data can be uploaded to a mobile phone or transmitted to the Environmental Protection Agency, other monitoring centers, monitoring equipment, and monitoring computers via a local area network or the Internet. The concentration of the site can be monitored in real time through free upper computer software or gas alarm controllers.

●Compatible with various secondary meters, data acquisition modules, PLC, DCS systems, can directly drive solenoid valves, fans, alarms and other equipment, and can also drive high-power equipment by driving intermediate relays. Optional MIC2000 controller can monitor 1000 detectors at the same time.

●Large-capacity data storage function, can record real-time concentration value, temperature and humidity, or only alarm value and time. Support local storage or SD card storage, please specify when ordering larger capacity. SD card storage capacity can be customized. Data export and analysis are carried out through the free upper computer software, and data can be viewed or deleted on the machine. It can be set to automatically overwrite data or not to overwrite data when the capacity is insufficient, and automatically stop recording.

●The standard infrared remote control can realize the operation without opening the cover in dangerous situations, such as: modify the alarm point, concentration calibration, zero point calibration, silence, restore the factory, enter the menu, view the record, 4mA output, 20mA output (calibrate other acquisition equipment) This function is required).

●Chinese and English interface can be selected, the default Chinese interface, support free switching of gas concentration units, conventional gas does not need to enter the molecular weight, and the molecular weight of special gas is automatically calculated and switched after entering the molecular weight. The units are optional: PPM, mg/m3, Vol%, LEL% , PPHM, ppb, mg/L

●The 2.5-inch high-definition color screen (LCM) displays real-time concentration, time, temperature, humidity, storage status and other information, and can simultaneously detect 1 to 6 gas concentrations and temperature and humidity. The menu interface uses high-definition simulation icons to display the function names of each menu , Concise Chinese or English operation prompts.

●Three display modes can be switched: simultaneous display of multiple gas concentrations, large font cycle display of single channel gas concentration, real-time curve, automatic or manual cycle between channels can be switched, you can set whether to display the maximum value, minimum value, gas name , You can view the historical record graph.

●Automatically track the zero point to prevent drift, temperature compensation, multi-level calibration, which can meet the national standard and the standards of the local and provincial metrology bureaus in various regions at the same time

●Data recovery function, automatic identification and prevention of incorrect operation of concentration calibration, which can avoid defects caused by improper operation.

●Can record calibration log, maintenance log, troubleshooting countermeasures, reminder of the expiration of sensor life, reminder of the next concentration calibration time

| Detection gas | Combustible gas(EX) | ||||

| Measure range | 0-1000、5000、10000ppm、5、50、100%Vol、100%LEL | ||||

| Resolution | 1PPM /0.1%VOL/ 0.1%LEL | ||||

| Principle | Infrared Principle | ||||

| Sensor life | 10years | ||||

| Allowable error | ≤±1%F.S | ||||

| Linearity | ≤±1% | ||||

| Response time | T90≤30S | Repeatability | ≤±1% | Uncertainty | ≤±1% |

| Signal output | Bus system RS485 (RTU), three (four) wire system | Recovery Time | ≤30S | ||

| Working environment | Temperature: -40℃~+70℃, humidity: ≤10~95%RH (normal) non-condensing occasions | ||||

| Display method | On-site 2.5-inch high-definition color screen display, optional on-site no display, or optional MIC2000 controller for remote display, control, and alarm | ||||

| Operating Voltage | 12~36VDC DC, the standard power supply of a single device is 24V, 1A or greater than 1A DC regulated switching power supply | ||||

| Power consumption | Maximum instantaneous current: 60 mA for electrochemical principle, 120 mA for catalytic or infrared principle | ||||

| Power reference | 24V, 2.1A switching power supply can drive 30 toxic gas detectors, or 15 combustible and infrared gas detectors | ||||

| Way of working | On-line installation, on-line inspection, diffusion measurement; pipeline, flow, and pump-suction measurement are available. | ||||

| Installation method | Pipeline type and wall-mounted type. The working pressure of the pipeline type is ±30% of the atmospheric pressure, and the pressure needs to be reduced if it exceeds the range. | ||||

| Alarm method | The default is 1 channel, optional 3 passive contact (dry node) output, three-level alarm, and the alarm point can be set. On-site sound and light alarm (optional). | ||||

| Connecting cables | 4-20mA three-core shielded cable, RS485 four-core, single wire diameter ≥ 1.5mm when the distance exceeds 1000 meters; both ends of the shielding layer are connected to the earth and ensure good grounding. | ||||

| Protection level | IP66, Waterproof and short-term rain | ||||

| Explosion-proof | Flameproof, Exd IIC T6 Gb | ||||

| Dimensions | 260×180×90mm (L×H×W) large air chamber 260×230×90mm (L×H×W) large air chamber with alarm 240×180×90mm (L×H×W) conventional air chamber 240×230×90mm(L×H×W) conventional with alarm | ||||

| Weight | Without alarm 2.2Kg/With alarm 2.4kg | ||||

| Optional accessories | Integrated warning light, power adapter, split warning light, drying cylinder, flow-through connector, threaded welding seat, AC AC pump, DC brushless pump, vacuum pump, rain cover, water vapor filter, U-shaped buckle, 304/ 316/316L stainless steel gas chamber, 304/316/316L stainless steel housing | ||||

| Optional function | Wireless transmission, Hart protocol output, split detection, temperature and humidity detection | ||||

SKZ Industrial Co., Limited and SKZ International Co., Limited are the members of

SKZ, which are specialized in supply Gas Detector. SKZ established in the year of 2006,

In the year 2018, we got our trade mark: SKZ, which we are so Treasured.

We have online shop on Alibaba and Aliexpress, which

have self-branded SKZ, good reputation, full customization, fast delivery and quick

response. Through the SGS/TUV field certification

We have over 15 years experience in the field, centralized procurement available,

We care about your lab, more concerned about your experience.

Our products have been exported to Southeast Asia, Australia, Africa, America, the

European Union and the Middle East .

1818

1818