1. The furnace body is heated by double – row winding of precious metal nickel – cadmium alloy wire, reducing interference and being more resistant to high temperatures.

2. The tray sensor made of precious metal alloy wire has advantages like high – temperature resistance, oxidation resistance, and corrosion resistance.

3. The power supply and circulating heat dissipation part are separated from the main machine, and the top – opening structure makes it easy to operate.

4. It uses an imported ARM processor for faster sampling and processing. The software has features like four – channel sampling AD, PID – controlled heating, USB two – way communication, and a 7 – inch full – color touch screen for a good user experience.

5. It has a wide temperature range, high temperature resolution, small temperature fluctuation, and a wide DSC measuring range, suitable for various material analysis applications.

Simultaneous thermal analysis (DSC/DTA, TGA) is a combination of differential heating and thermo gravimetric. It can not only study the change of sample quality with temperature or time in the process of heating and constant temperature, but also study and analyze the change process of the sample, by the heat generated changes. The purpose is to study the thermal stability and composition of the material.

Widely used in the research and development, process optimization and quality control of plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composite materials

Application range:

Thermal stability, decomposing process, adsorption and desorption, oxidation and reduction, ingredients quantitative analysis, additives and filler influence, moisture and volatiles, reaction kinetics.

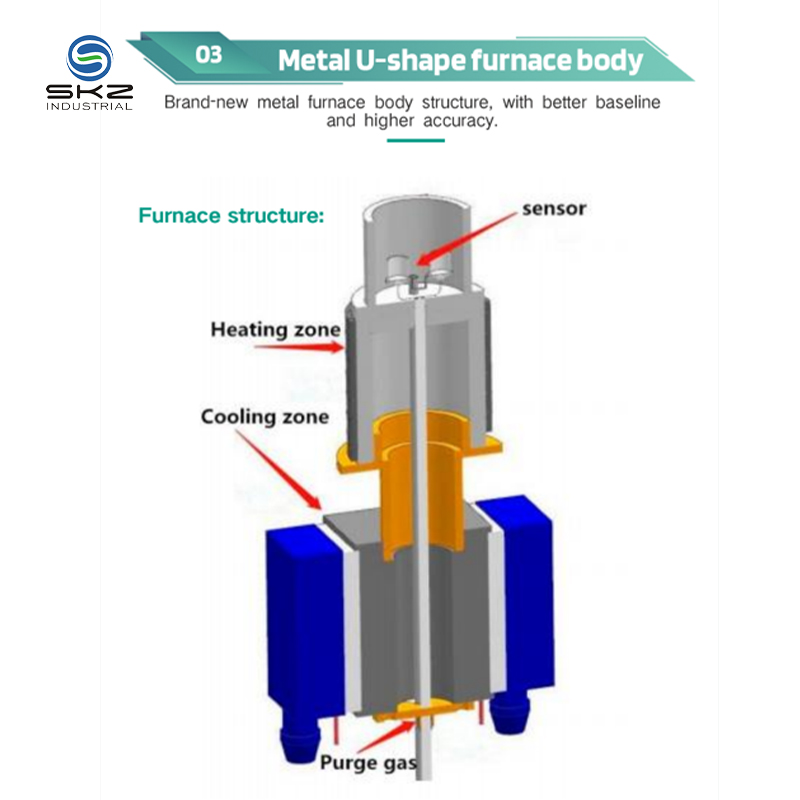

Structural advantages:

1. The furnace body is heated by double-row winding of precious metal nickel-cadmium alloy wire, which reduces interference and is more resistant to high temperatures.

2. The tray sensor is made of precious metal alloy wire, which has the advantages of high temperature resistance, oxidation resistance and corrosion resistance.

3. The power supply and circulating heat dissipation part are separated from the main machine to reduce the influence of heat and vibration on the micro-thermal balance.

4. Adopt top-opening structure, easy to operate. It is difficult to move the furnace body up to place the sample, and it is easy to damage the sample rod.

5. The host uses the heat insulation of the heating furnace body to the chassis and micro-thermal balance.

6. The furnace body can be replaced according to customer requirements

Controller and software advantages:

1. Using imported ARM processor, sampling speed, processing speed is faster.

2. Four-channel sampling AD collects TG signal and temperature T signal.

3. Heating control, using PID algorithm, precise control. Multi-stage heating and constant temperature

4. The USB two-way communication is adopted between the software and the instrument to fully realize remote operation. The parameter setting of the instrument and the operation and stop of the instrument can be carried out through the computer software.

5. 7-inch full-color 24bit touch screen, better man-machine interface. TG calibration can be achieved on the touch screen

Technical parameters:

| Display | 7 inches LCD color screen display |

| Temperature range | Room temperature ~1150℃(SKZ1060A),

1350℃(SKZ1060B) 1550℃(SKZ1060C) |

| Temperature resolution | 0.01 ℃ |

| Temperature fluctuation | ±0.1℃ |

| Heating rate | 1 — 100 C/ min |

| Temperature control mode | Temperature rise/fall and constant |

| Constant temperature time | 0–300min, Can be set |

| Cooling time | 15min (1000C~100C) |

| Scale Capacity | 1mg—3g (Optional 10g) |

| DSC measuring range | 0—±500mW |

| DSC Resolution | 0.01uW |

| Resolution | 0.01mg |

| Constant temperature time | 0 –300min Can be set |

| Atmosphere | Inertia, oxidability, reducibility, static and dynamic |

| Atmosphere device | Built-in gas flow meter |

| Software | Professional operating software |

| Data interface | USB |

| Power | AC220V 50Hz |

| Size | 500*400*430mm |

| Host machine | 1 set |

| U DISCK with installation system | 1 piece |

| Power Cord | 1 piece |

| Data line | 2 pieces |

| Sample crucible | 100 pieces |

| 10A fuse | 5 pieces |

| Operational manual | 1 piece |